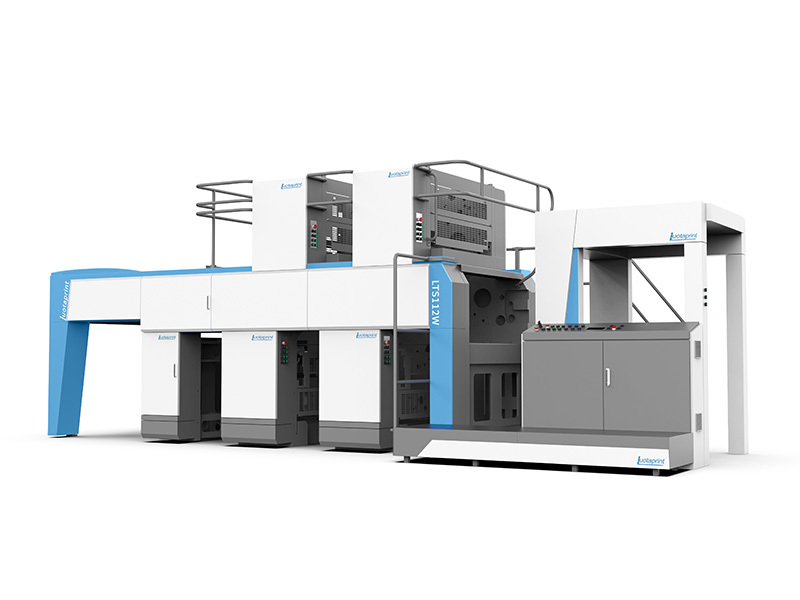

VSOP-850 Commercial Rotary Press

Classification:

Key words: printing machinery manufacturing丨double-sided offset printing machine丨rotary printing machine丨computer bill printing machine

Product Description

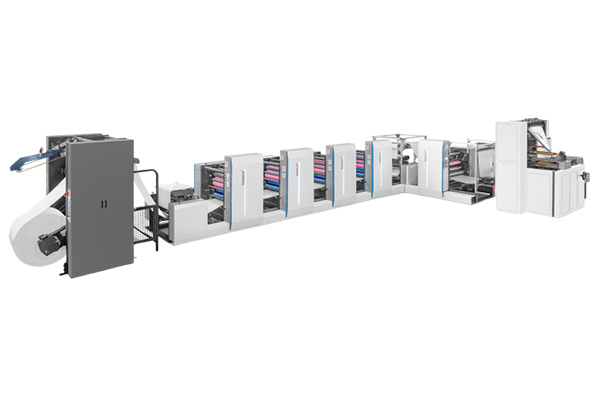

VSOP is the abbreviation of the English Variable Sleeve Offset Press, which means offset printing machine with variable size sleeve simplification technology in Chinese. Its simple technology can quickly and easily change sizes and orders, greatly improving the flexibility of production. VSOP is a product produced by our company in recent years in technical cooperation with the Dutch company Scooden. Compared with gravure printing and flexo printing, it has the advantages of cheap plate material, fast plate making, short prepress preparation time, more exquisite graphics and text, and no VOC emission. It can also combine flexo printing, gravure printing, screen printing and digital printing processes to meet the quality needs of customers.

The first offset film printing machine in China, advanced non-shaft transmission technology, suitable for soft bag printing of various materials!

Sino-foreign cooperation, sleeve technology, quick replacement;

No VOC emission green printing;

The low cost of plate making is only 5% of intaglio;

The plate-making time is 15 minutes short;

Glue, soft, concave combination printing.

VSOP Applicable Market

Label printing: paper and plastic wrap-around labels, self-adhesive labels, in-filmLabel, shrink sleeve label

Soft bag printing: paper and plastic film for food packaging, handbags

Cardboard printing: carton and carton preprinted

| Main technical parameters | |

|

Width of printing material |

850mm |

|

Maximum printing width |

830mm |

| Maximum mechanical speed | 400 m/min |

| Repeat printing length | (Perimeter) 406-762 |

| Maximum diameter | 1270mm |

| Sleeve size change | infinite change |

| Plate type and thickness | Offset printing traditional PS version, offset printing CTP version or waterless offset printing version thickness 0.3mm |

| Thickness range of printing material | 12-200 microns |

|

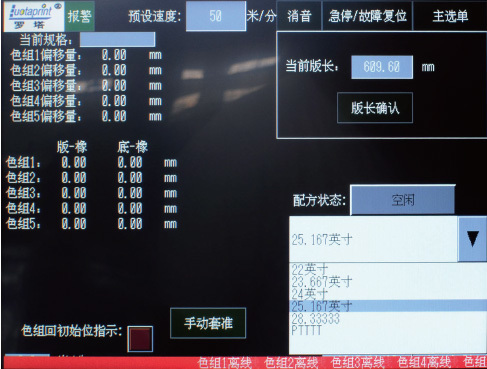

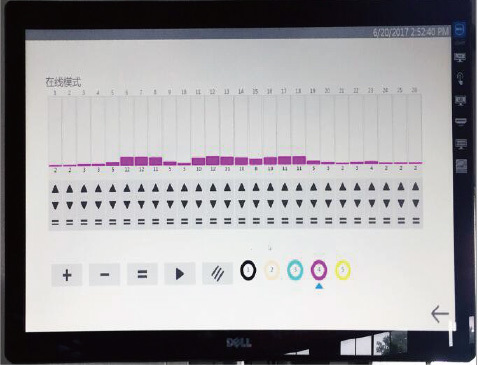

1. Main control system

Using German Rexroth control technology, the use of servo motor directly drive all units, in the printing process, precise control of tension and overprint accuracy. |

2. Feeding Department |

| 3. Dust removal and corona |

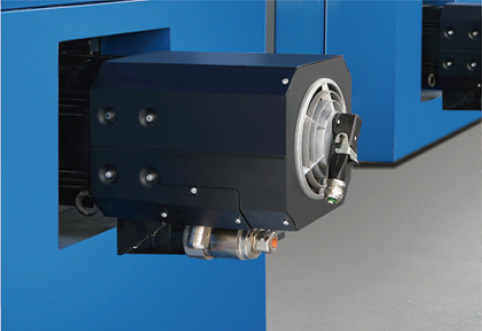

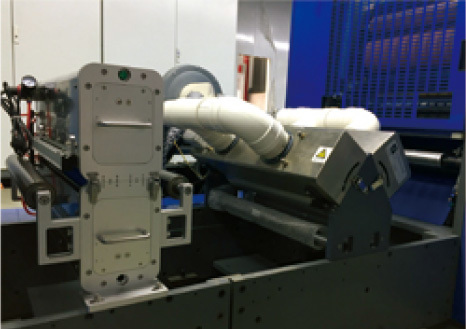

4. Offset color group |

| 5. Sleeve technology |

6. Curing and drying |

| 7. Flexo color group |

8. Automatic registration |

| 9, Printing Monitoring |

10. Material receiving department |

| 11, Information Management |

12. Ink management |

关键词: VSOP-850 Commercial Rotary Press

Previous Page

Next Page

recommend products

Welcome your message consultation

E-mail: info@luota.com

E-mail: info@luota.com

Address: Group 4, He Yang Village, Rucheng Street, Rugao City

Address: Group 4, He Yang Village, Rucheng Street, Rugao City