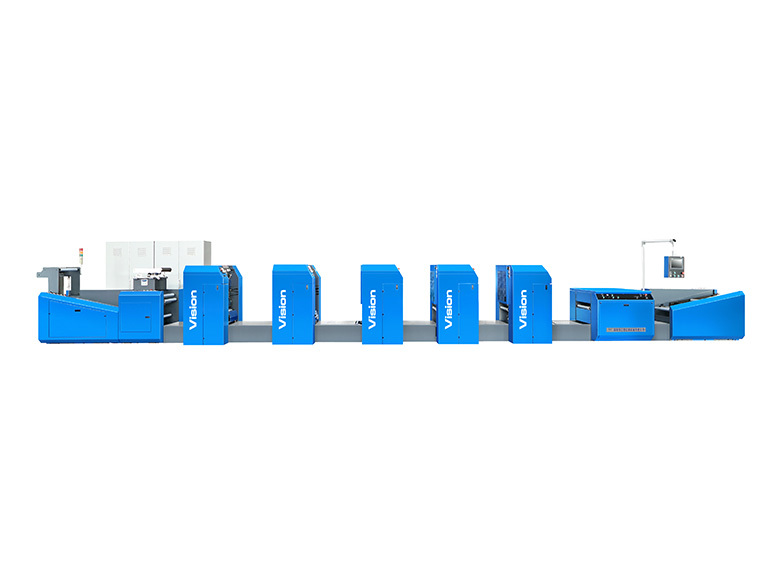

Vision Commercial Rotary Press

Classification:

Key words: printing machinery manufacturing丨double-sided offset printing machine丨rotary printing machine丨computer bill printing machine

Product Description

Vision Commercial Rotary Press

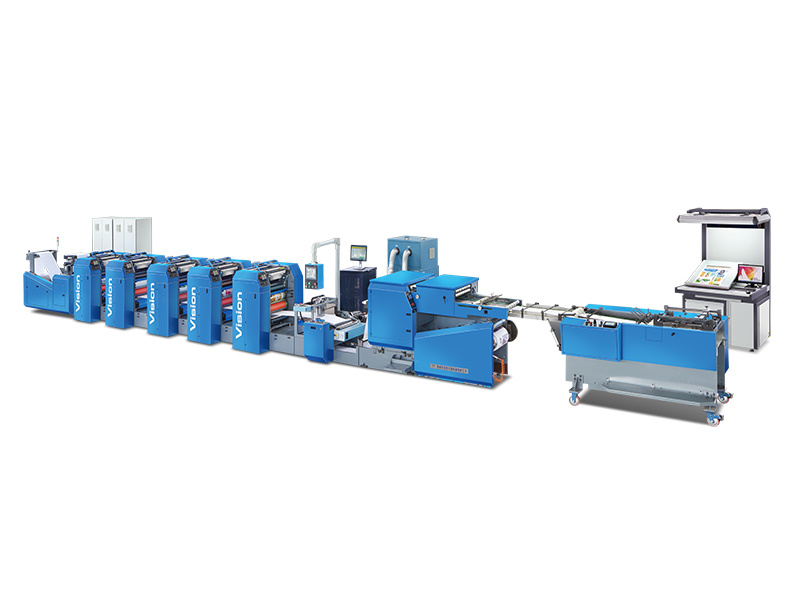

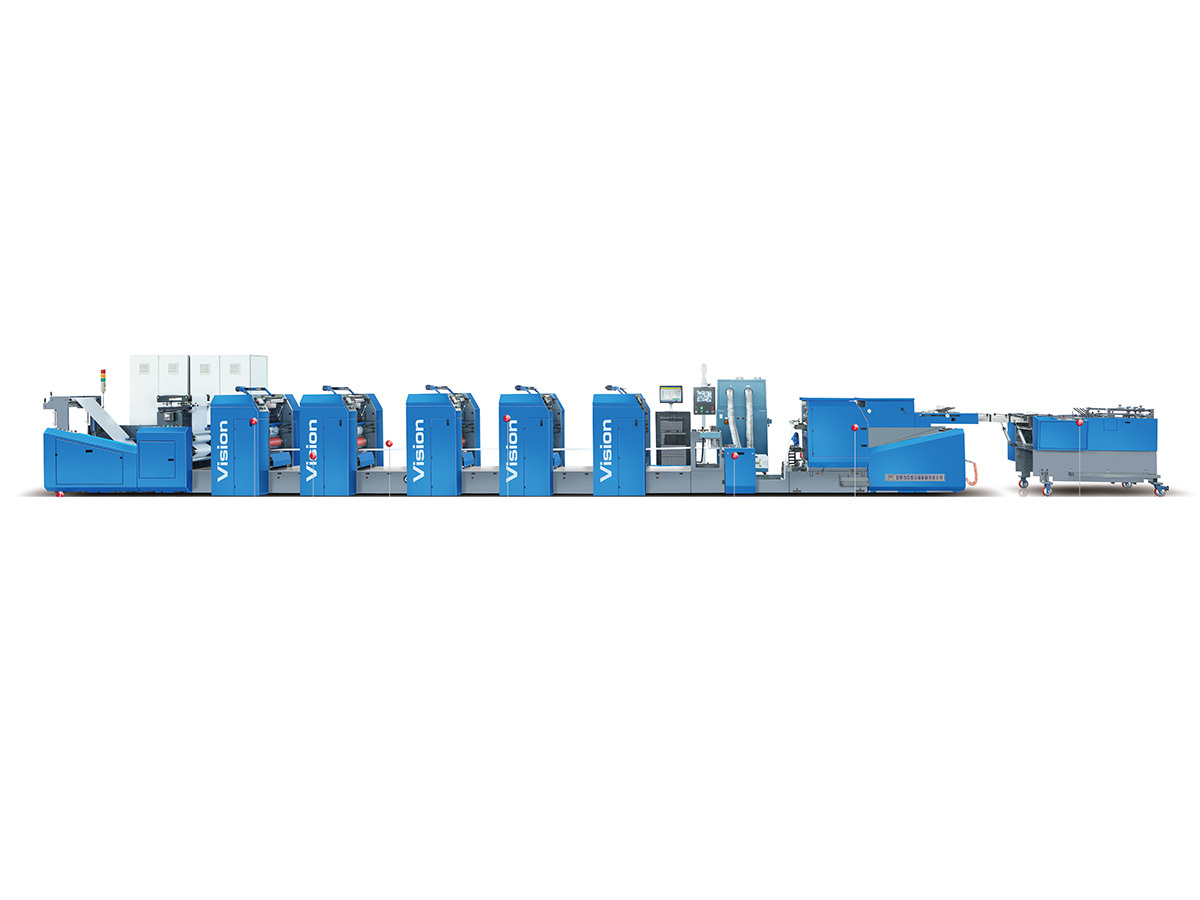

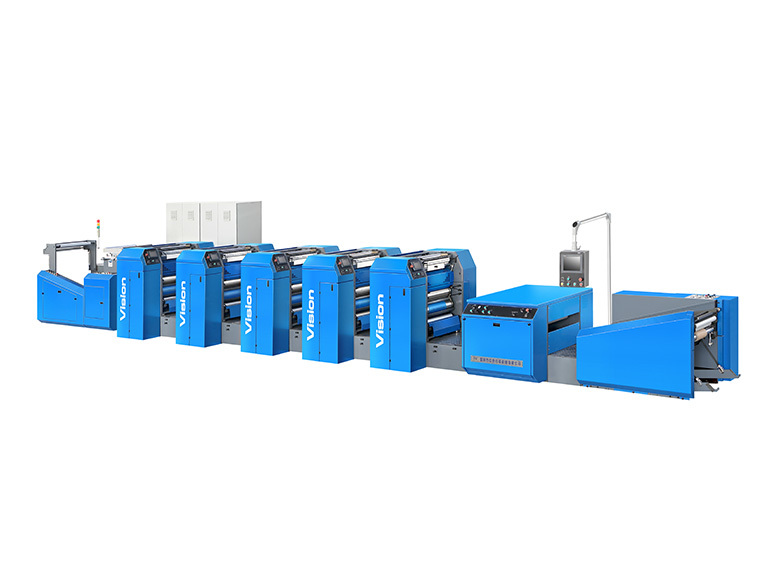

The Vision commercial rotary press is a mature and perfect product designed by the Dutch company Drent, which has nearly 70 years of experience in manufacturing offset presses. The combination of mature shaftless rotation technology and printing technology greatly reduces the preparation time. Vision commercial rotary presses have the competitive advantages of modern presses in terms of productivity, versatility and order turnaround time.

Vision commercial rotary press is a short preparation time, can be any combination of shaftless drive technology rotary offset printing press. This offset press can be used for a wide variety of products, including commercial printing, direct mail products, labeling, pharmaceutical embedding and various flexible packaging applications.

The modular design enables customers to achieve any combination of printing requirements, making it suitable for a wide variety of products. An optional module enables on-line post-press processing.

|

|

|

|

| Servo drive | Information Management | Quick change of color group | Automatic cleaning |

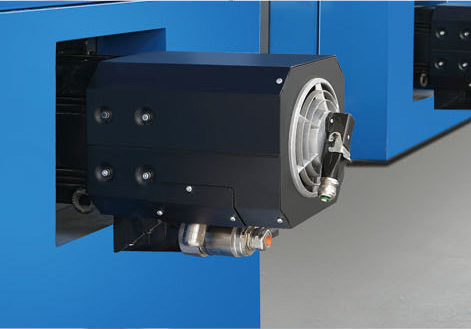

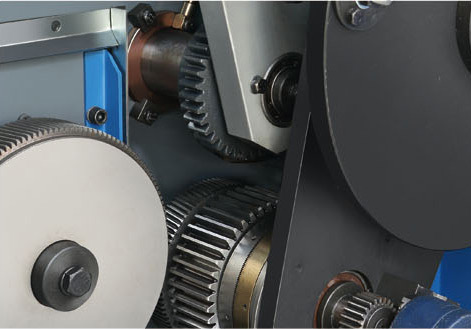

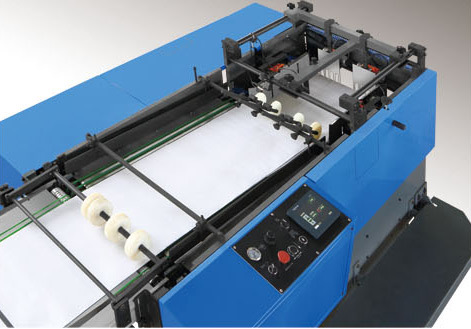

| Cancel the traditional gear transmission and gear box, using the new control technology of German Rexroth, using servo motor to directly drive all the units, can make the printing material from 12 to 300 microns thickness. Tension and printing registration are precisely controlled, and the registration can also remain stable when changing speeds. |

The operator interface may be configured by the software to repeat orders. The software allows the printing color group to keep the relevant settings on the CD or hard drive, and the machine can retrieve the previous working settings when processing orders repeatedly. This results in a 70% time saving. |

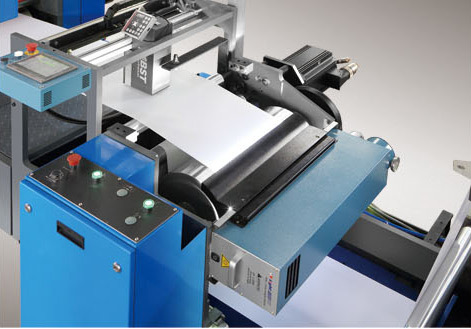

The press set is equipped with built-in three groups of cylinders. When the size color group is put back in the printing unit, it will automatically adjust to the correct position. The cylinder will be automatically set to the zero position. Replacement of four size color groups within ten minutes |

The Vision commercial rotary press's automatic cleaning system cleans the ink rollers in all ink paths. Each printing unit can be cleaned independently or simultaneously. |

|

|

|

|

| Mixed Printing | Drying | Cutting Department | Flat sheet receiving department |

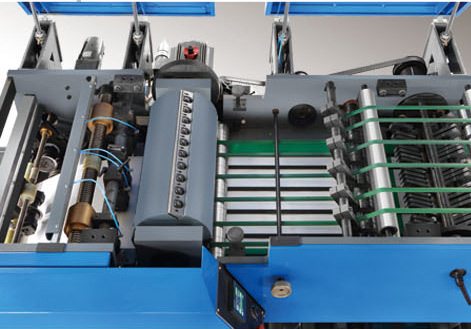

| The Vision commercial rotary press can be implemented with up to 40 independently driven printing, processing and switching modules. Each module drive uses an electronic axis connection and is controlled by a motion controller, rather than by a mechanical connection. The post-press configuration can be easily changed or added to various modules, such as die-cutting, punching, numbering, cutting sheets, etc. The printing color group modularity can add flexo, gravure, embossing and rotary screen printing modules. To achieve a variety of printing requirements. |

Vision commercial rotary presses can be configured with different drying methods. UV drying, hot air drying, infrared drying, electron beam drying or high frequency drying. UV drying is often the solution for difficult printing processes and temperature sensitive printing materials. |

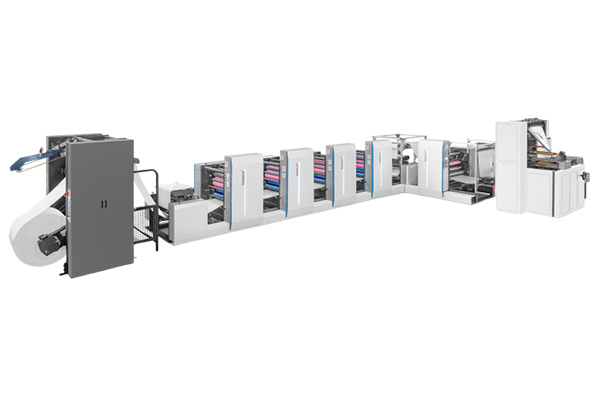

The single cutting section adopts shaftless transmission technology, with high cutting accuracy, and the cutting section also has the function of longitudinal cutting. There is no need to replace accessories when the size changes, and the cutting of different sizes can be completed with simple data setting. The cutting method is shear type, durable. The single sheet cutting part and the roll paper receiving part share a platform. When cutting is not needed, the single sheet cutting part can be translated horizontally. |

The flat sheet receiving part is a movable platform, which is easy to operate. The paper delivery methods are: flat stack type and belt fixed number conveying type, and both are non-stop paper delivery. |

|

Ink control Ink color control is divided into ink color remote control system and ink quantity preset system software. The ink color remote control system is a precise digital ink color control device for the printing machine. The system divides the ink fountain roller into several equal parts, corresponding to several control ink knives, each ink knife is controlled by a motor. The system uses advanced information sampling and data processing methods to achieve precise control of ink volume by changing the gap size between the ink knife and the rotating ink fountain roller. The ink quantity preset system uses the electronic documents generated in the digital workflow to obtain the statistical distribution data of the layout color separation information, automatically determines the ink quantity of the ink area, and transmits the ink quantity information to the ink color remote control system to complete the ink quantity preset before printing. Vision Advantages Vision 的优势 Advanced offset printing quality Short preparation and conversion time Many different in-line machining functions Humanized and ergonomic operation. |

| Main technical parameters | |

| Width of roll material |

520mm(max)一200mm(min) |

| unwinding diameter | max.1270mm(50") |

| Scope of Materials | 20- 350 microns |

| Printing width | 508mm(max) |

| Main printing unit | Up to 12 printing units, variable size. |

| Alcohol dampening or letterpress printing. | |

| circumferential register | 360 degrees. |

| printing exchange cylinder | 16 inches to 28 inches, increasing in 1/6 inch increments. |

| Multi-function module options | Document holes, numbering, die cutting, flexographic printing, glazing, cutting leaflets, etc. |

| Rewinding diameter | max.1270mm(50") |

| Cut a leaflet | 4 inches to 28 inches, increasing in 1/6 inch increments. |

| Stack height | 800mm |

| Stacker car size | A3 paper or 11 "X17", A4 paper or 8 5 "X11", A5 paper or 5.5 "X8.5" |

| Maximum rated speed | 300 m/min, (1000ft/min) according to rewinding or cutting single conditions. |

| Other printing options (partial list) |

Drying (UV, hot air, infrared, electron beam, HF) |

| Embossing printing unit | |

| Rotary screen printing unit | |

| Digital Printing Unit | |

| Glue or paint unit | |

| All specifications are subject to change without notice | |

| Optional Configuration | |

| -Units that can be added | -Flexo printing unit |

| -Die cutting machine | -Screen printing unit |

| -Rewinder | -Gravure printing unit |

| -Repeat insert color group | -Bronzing units |

| -Paper trimmer | -Laminating device |

| -Blanket cleaning system | -Number unit |

| -Romote ink control | -UV curing cooling device |

| -registration system | -Hot air dryer for water-based or solvent-based inks |

| -Network video system | -pick up paper without stopping the machine |

| -UV curing system | -Corona unit |

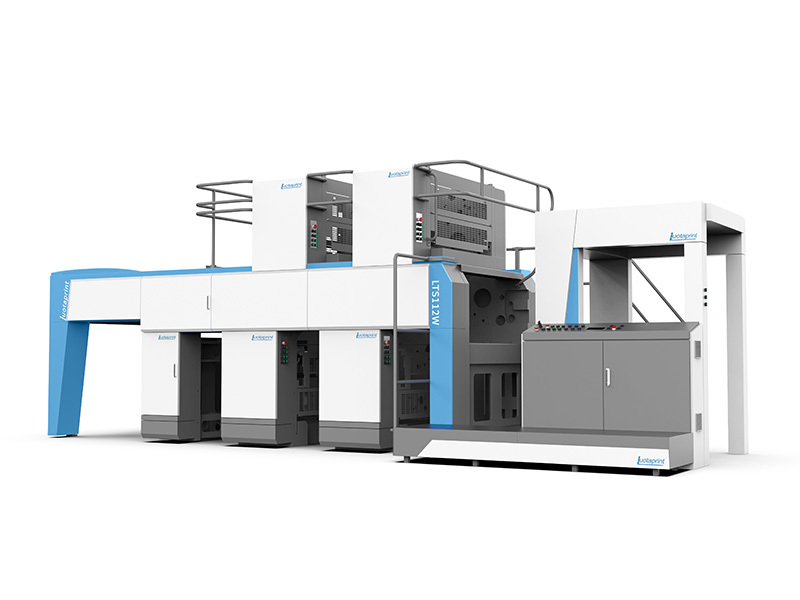

| The perfect and reliable solution | |

| -Reliable and perfect solution | -Lottery |

| -Commercial Printing | -Medical Packaging Products |

| -Direct Mail | -Commercial Forms |

| -(wrap around) tab | -Continuous Paper |

| -Anti-counterfeit printing | -Sheet-fed laser form |

| -CD Brochure | |

关键词: Vision Commercial Rotary Press

Previous Page

Next Page

recommend products

Welcome your message consultation

E-mail: info@luota.com

E-mail: info@luota.com

Address: Group 4, He Yang Village, Rucheng Street, Rugao City

Address: Group 4, He Yang Village, Rucheng Street, Rugao City