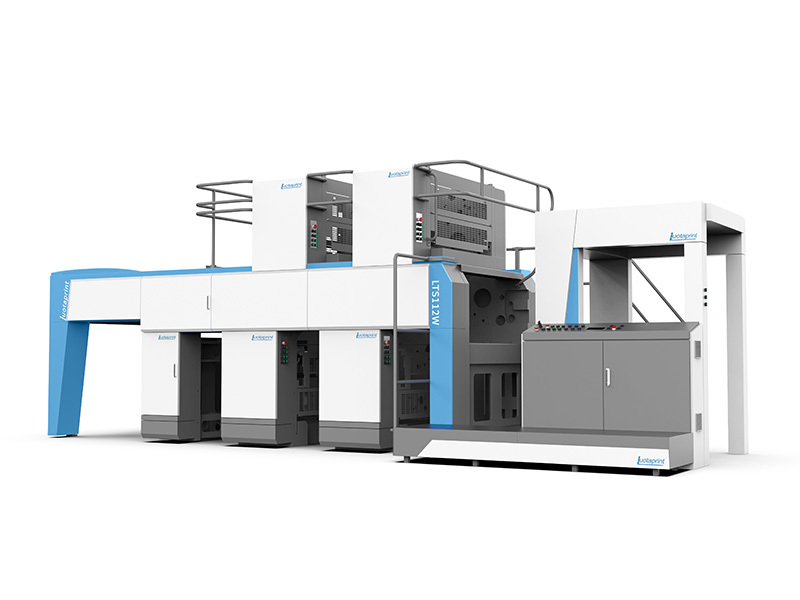

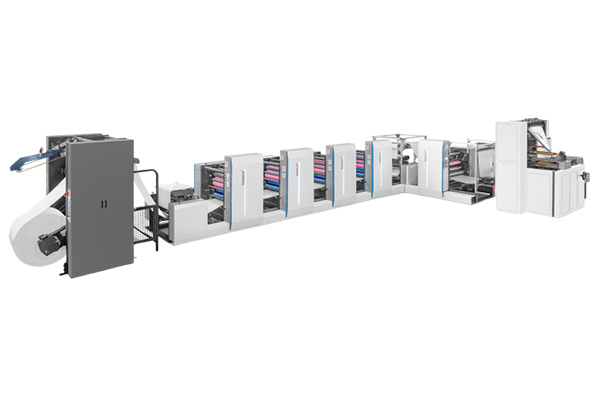

LTS104WJ-2 double-sided two-color printing online inspection machine

Classification:

Key words: printing machinery manufacturing丨double-sided offset printing machine丨rotary printing machine丨computer bill printing machine

Product Description

Working mode

In the working process, the printed goods are sent to the paper conveying table under the coordinated action of the paper dividing mechanism and the paper conveying mechanism of the paper conveying and separating head on the paper pile. After the speed change mechanism of the paper conveying machine and the deceleration treatment of the negative pressure paper conveying mechanism and the side specified position, the printed goods transferred at high speed are smoothly stopped at the front gauge position and wait for the paper to be handed over by the paper conveying mechanism.

When the printed product passes through the front gauge and the side gauge and is connected to the paper through the gripper, it passes through the front transfer rolling simplification, the middle transfer rolling simplification, the negative pressure roller for reverse detection, the negative pressure roller for front detection, the paper receiving rolling simplification, the waste bin and the genuine goods bin in a constrained gripper handover manner. Throughout the paper transfer process, the Chinese and Indian products are in a constrained state, and the positioning is accurate and does not change due to changes in speed.

The role of wind and negative pressure suction is to absorb the print flat to the surface of the cylinder, so that the detection system can more accurately collect the print image.

The function of the waste bin and the pneumatic tooth opening mechanism is to give an action signal to the paper receiving mechanism of the waste bin after the detection system detects the waste products. When the printed products pass through the waste bin, the mechanism acts to collect the waste products to the waste bin from the surface.

The main warehouse is used to collect qualified products.

The functions of lifting paper without stopping the machine, stacking paper outside the machine and collecting paper without stopping the machine are all used to reduce the downtime during the operation of the equipment and improve the work efficiency.

Features

This inspection machine is suitable for double-sided inspection of all kinds of instructions, all kinds of books and periodicals and all kinds of color packaging printing. It is suitable for printing with a gram weight range of 40g-400g, and has a constrained handover in the whole process. It can highlight its high efficiency and high stability in the inspection of thin paper printing.

|

Main technical parameters

|

||

|

Specifications and models |

LTS104WJ-1 | LTS104WJ-2 |

| Maximum Paper Size (mm) | 720X1040 | 720X1040 |

| Minimum Paper Size (mm) | 360X520 | 360X520 |

| Maximum printing area (mm) | 700X1040 | 700X1040 |

| Maximum printing speed (r.p.h) | 13000 | 13000 |

| Paper thickness (mm) | 0.04-0.2 | 0.04-0.2 |

| Plate size (mm) | 1055X800X0.28 | 1055X800X0.28 |

| Bottom backing paper (mm) | 1055X800X0.15 | 1055X800X0.15 |

| Blanket Size (mm) | 1055X960X1.9 | 1055X960X1.9 |

| Height of paper table (mm) | 1100 | 1100 |

| Delivery table height mm) | 910 | 910 |

| Machine Size (mm) | 8000X3800X2850 | 8000X3800X2850 |

| Total machine power (kw) | 25 | 50 |

| Main motor power (kw) | 15 | 30 |

| Machine weight (T) | 22 | 27 |

| Specific borrowing amount (circumferential) mm | -0.8~ 0.8 | -0.8~ 0.8 |

| (Axial) mm | -2~ 2 | -2~ 2 |

| Product parameters are subject to change without notice | ||

关键词: LTS104WJ-2 double-sided two-color printing online inspection machine

Next Page

recommend products

Welcome your message consultation

E-mail: info@luota.com

E-mail: info@luota.com

Address: Group 4, He Yang Village, Rucheng Street, Rugao City

Address: Group 4, He Yang Village, Rucheng Street, Rugao City