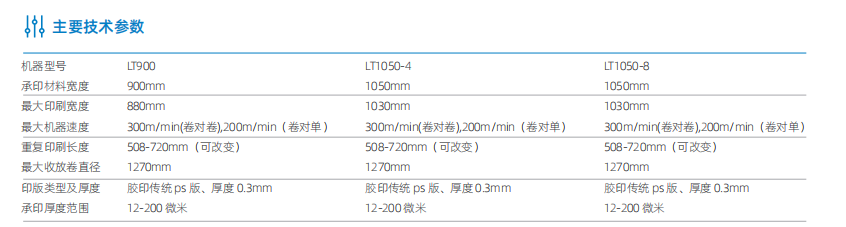

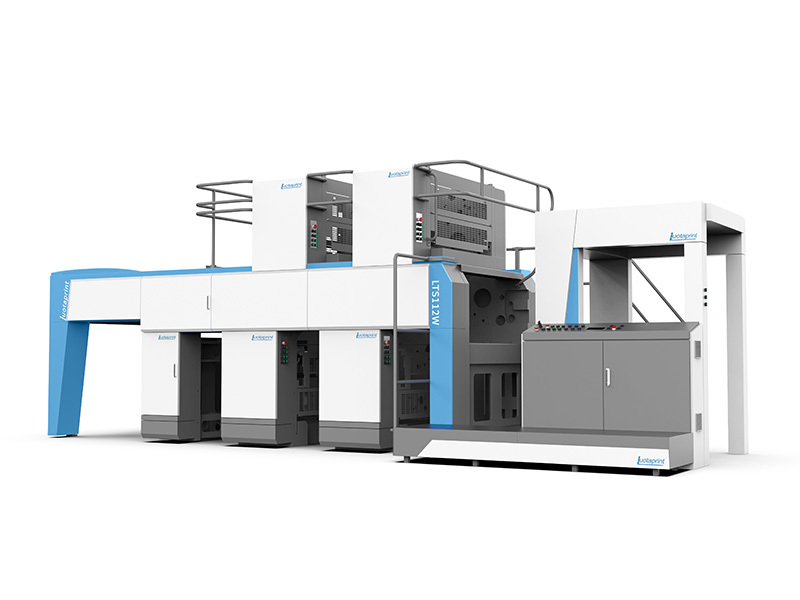

LT900/1050 Variable Size Hard Press Soft Commercial Rotary Offset Press

Classification:

Key words: printing machinery manufacturing丨double-sided offset printing machine丨rotary printing machine丨computer bill printing machine

Product Description

Equipment Introduction

Rugao Zhongluo Printing Machinery Co., Ltd. is located in Rugao, Jiangsu, the hometown of longevity in the world. It is a high-tech enterprise specializing in the production of "Rota" brand double-sided offset press, Vision and VSOP commercial rotary press.

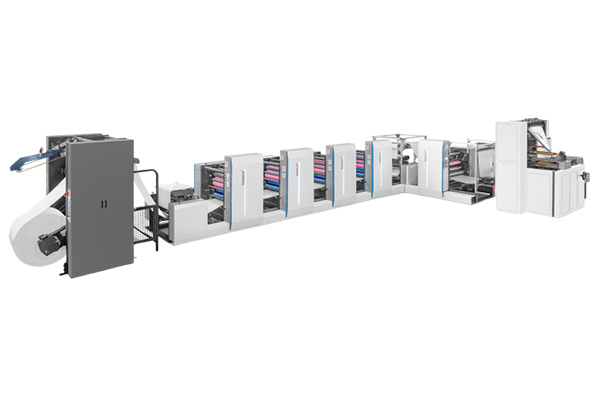

In 2018, after digesting and absorbing international advanced technology, our company developed a hard-pressing soft LT1050 rotary offset printing machine with a printing speed of up to 300 m/min (paper size 720 × 1050mm) and variable size (circumference 508-720mm).

This model can replace the printing cylinder, realize printing and cutting of various sizes on the same machine, solve the customer's concerns about product size and selection in purchasing products, can be folded or divided into single sheets, realize a number of automation and intelligence, make high-speed, high-efficiency, high-intelligence and high quality double-sided rotary printing a reality, and fill the domestic gap!

Host Configuration

Unwinding part

* Double station, unwinding without stopping the machine;

* The paper roll is connected by lap joint;

* With a large paper storage library, built-in unwinding tension control;

Printing Unit

Printed wallboard for box plate structure: 900*1590*50, material Q345B.

* The main bearing of printing cylinder adopts INA bearing.

* The printing cylinder is equipped with a skew adjustment device and is driven by a servo motor.

* The machine running printing cylinder radial axial register using servo motor drive.

* Each ink supply system has three ink rollers, three ink string rollers, one ink transfer roller, ink fountain roller and five

Ink roller. A total of 13, can be used for packaging printing

* The water supply system has a water roller, a water transfer roller and a bucket roller.

* The ink fountain is tipping bucket type, and the ink quantity control adopts 26 ink zones for quantitative adjustment.

* The driving mode of ink fountain roller is independent motor transmission;

* The ink and water string mechanism adopts the eccentric swing of the structural disc in the patent (ZL2013 2 0131871.8);

* The surface of the ink roller is plated with nylon, which can be equipped with a cooling ink system and a cooling water tank;

* The bucket roller is driven by a separate motor;

* The water bucket adopts simple single-layer structure with external insulation material;

* The water transfer roller is driven by gears and synchronous toothed belts, and the power comes from the bucket roller motor;

* The surface of the string roller is chrome-plated;

* Water regulation can track the host speed or separate speed regulation;

* The clutch of the ink roller, the water roller and the ink transfer roller is realized by the cylinder control;

* The operating surface adopts a new type of casing, beautiful appearance, convenient operation;

* Oil shower lubrication of gears, bearings and eccentric bearing seats in the box body through the thin oil circulation system.

Insufficient quantity will automatically alarm;

* The main bearings of the operating surface are lubricated with grease;

Front Tension System

* A set of bottom roller pressure roller system, the bottom roller is driven by a servo motor;

* A tension detection roller, equipped with Germany E L high-precision pressure sensor;

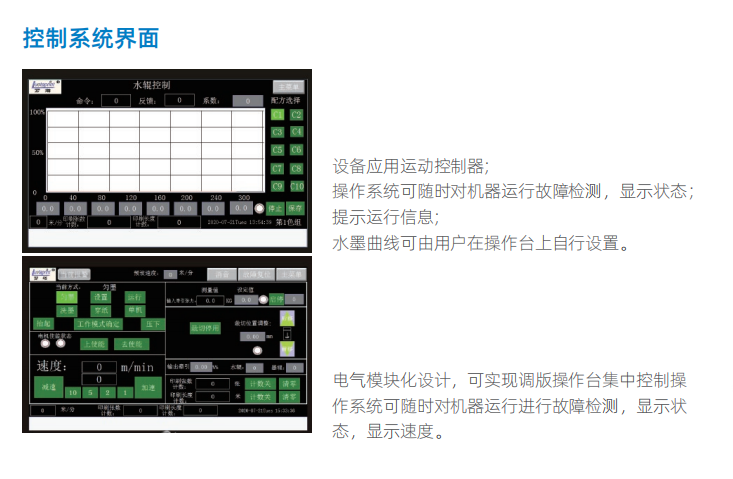

electrical control system

* China-Romania LYPQ1050 control system;

* The electrical control system adopts advanced component configuration, relays, contactors and other low-voltage electrical appliances with France

Schneider products;

* The whole machine logic, printing program, whole deceleration and other digital quantity, analog quantity signal all by the PLC internal process

Direct sequence control;

* The main drive adopts shaftless drive control, and the main motor is Austrian Baikal motor;

* all kinds of printing color group can be carried out separately, off-line operation;

* Speed, water volume, register, counter, etc. are displayed by man-machine interface;

* Advanced machine operation console.

Quality inspection system (optional)

* Ultrasonic and infrared broken paper detection device;

* Germany BST fully automatic registration system;

* Germany BST still picture system;

* German BST full screen detection system or another brand by customer association.

Other auxiliary machines

* Germany E L tension control 1 set;

* bending plate punching machine, for making PS plates;

* fountain liquid tank, with circulating pump, with alcohol automatic ratio function;

关键词: LT900/1050 Variable Size Hard Press Soft Commercial Rotary Offset Press

Next Page

recommend products

Welcome your message consultation

E-mail: info@luota.com

E-mail: info@luota.com

Address: Group 4, He Yang Village, Rucheng Street, Rugao City

Address: Group 4, He Yang Village, Rucheng Street, Rugao City